Our electrical hot water power washers are exceptionally well-engineered systems that provide the "Best Added Value in the Market" for commercial and industrial applications!

Blog

Foamers are chemical applicators that use compressed air to create thick foam that can be projected onto any surface. Foamers greatly improve the effectiveness of cleaners and disinfectants since they increase the surface dwell time and assure complete coverage. Using foam also reduces the over-application of chemical since you can see exactly where the chemical has been applied.

Foamer Applications

- Large Area Foam Cleaning

- Food & Beverage Processing

- Industrial

- Metal Processing

- Military

- Farming

- Paper Mills

- Odor Control

Foamers are available in a variety of configurations to suit large or small jobs. They can be used as a pre-wash, a post-wash disinfectant, or general wash in facilities where plumbed water is unavailable. In facilities without compressed air, foamers can use boosted water pressure, a venturi injection system and atmospheric air to create foam.

A range of foam volumes and throw distances are available. We can recommend the best model to use based on your application and desired coverage speed. Wall mount models include heavy-duty stainless steel mounting enclosures and portable models feature heavy-duty stainless steel carts.

Air Pump-Fed Foamers

These units are powered by compressed air and are designed for use in facilities where plumbed water pressure is unavailable, unreliable or lower than the 35 PSI required. An air-operated diaphragm pump, mounted inside a stainless steel enclosure, draws and pressurizes a ready-to-use chemical solution to produce foam and project it through the hose, wand and nozzle to any surface up to 15 feet. The portable model draws pre-diluted chemical from an integrated tank on a cart and the mounted model draws from a customer-supplied stationary tank.

Portable Features

- Rugged 1/2″ air-operated, double-diaphragm pump

- Lockable stainless steel pump enclosure

- Air inlet ball valve and regulator/filter

- Machined poly foamer body

- Integrated 20, 40 or 60 gallon poly chemical concentrate tank with strainer

- All stainless steel 4-wheel cart with integrated hose rack

- Non-marking tires w/SS swivel casters – (2) rigid and (2) swivel

- Single or dual hoses with Open Flow Wands

- Adjustable foam consistency (wet/dry)

Wall-Mounted Features

- Rugged 1/2″ air-operated, double-diaphragm pump

- Lockable stainless steel pump enclosure

- Air inlet ball valve and regulator/filter

- Machined poly foamer body

- 50′ discharge hose & stainless steel ball valve

- Stainless steel foam wand & fan nozzle

- Provides 8 minutes of foaming time per 20 gallons of solution

- Covers up to 500 sq ft (46.5 sq m) in 1 minute

- Adjustable foam consistency (wet/dry)

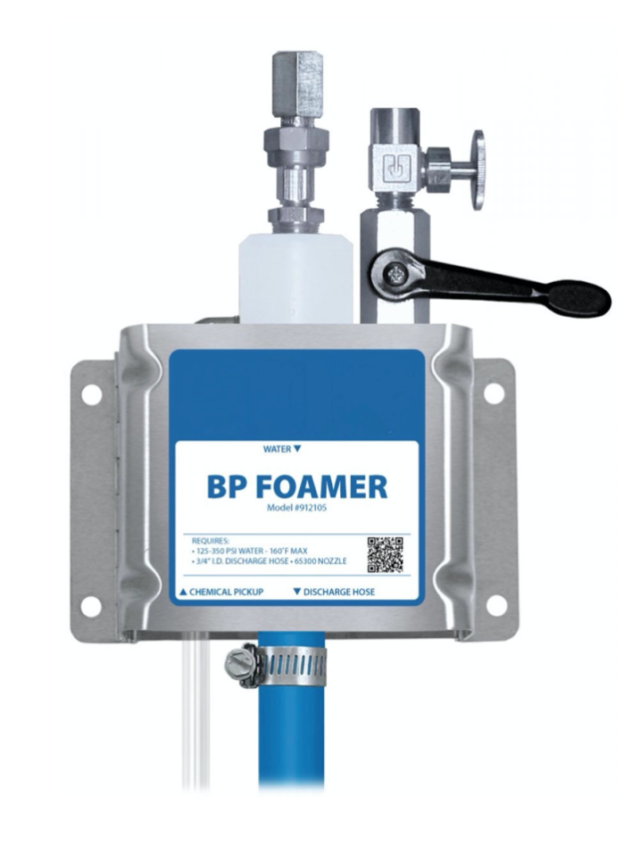

Boosted & High Water Pressure Venturi Foamers

These water-driven venturi injection systems use boosted water pressure (125-350 psi), high water pressure (400-1000 psi) or a pressure washer to draw and blend chemical concentrate from a tank into the water stream to create an accurately diluted solution. Air is injected into the solution to create the foam which is then projected through the nozzle onto surfaces at distances from 15 to 45 feet. The portable model draws pre-diluted chemical from an integrated tank on a cart and the mounted model draws from a customer-supplied stationary tank.

Portable Features

- Stainless steel 4-wheel cart with non-marking tires

- Two stainless steel swivel casters

- 20 or 60 gallon, wide-mouth, polyethylene chemical tank with drain

- Stainless steel water inlet ball valve

- Machined poly or stainless steel foamer body

- 20 color-coded precision metering tips to set dilution ratios

- 50’ discharge hose

- Poly or stainless steel foam wand

- Fan pattern nozzle for broad coverage

- Zero degree nozzle for high or distant coverage

- Adjustable foam consistency (wet/dry

- Available with other options

Wall-Mounted Features

- Stainless steel mounting bracket

- Machined poly or stainless steel foamer body

- 20 color-coded precision metering tips to set dilution ratios

- 50’ discharge hose

- Poly or stainless steel foam wand

- Fan pattern nozzle for broad coverage

- Zero degree nozzle for high or distant coverage

- Adjustable foam consistency (wet/dry)

- Available with ability to apply 2 chemicals at the same time

High Pressure Airless Foamers

Our Airless Foamers are medium to high volume foam applicators for projecting foaming chemicals without compressed air. Just attach it to a wall and connect it to a water source. These systems use venturi injection and boosted water pressure to draw and blend chemical concentrate into the water stream to create an accurately diluted solution. The solution then flows through the discharge hose and trigger gun to the “airless” foam wand that draws in atmospheric air to create foam. The foam can be projected on to any surface at distances up to 12 feet (depending on water pressure and nozzle).

Portable Features

- Uses boosted water pressure – HP (400-1000 psi)

- No compressed air required

- Designed for foam cleaning medium to large sized areas

- Stainless steel cart with stainless steel bucket strap, integrated hose rack and non-marking tires

- Stainless steel inlet ball valve

- Machined stainless steel or poly injector body

- 20 color-coded precision metering tips to set dilution ratios

- Discharge hose and trigger gun

- Stainless steel airless foam wand

Wall-Mounted Features

- Uses boosted water pressure – HP (400-1000 psi)

- No compressed air required

- Designed for foam cleaning medium to large sized areas

- Stainless steel inlet ball valve

- Machined stainless steel or poly injector body

- 20 color-coded precision metering tips to set dilution ratios

- Discharge hose and trigger gun

- Stainless steel airless foam wand

We can help you design multi-function systems consisting of proportioning, sanitizing, foaming and/or rinsing systems.

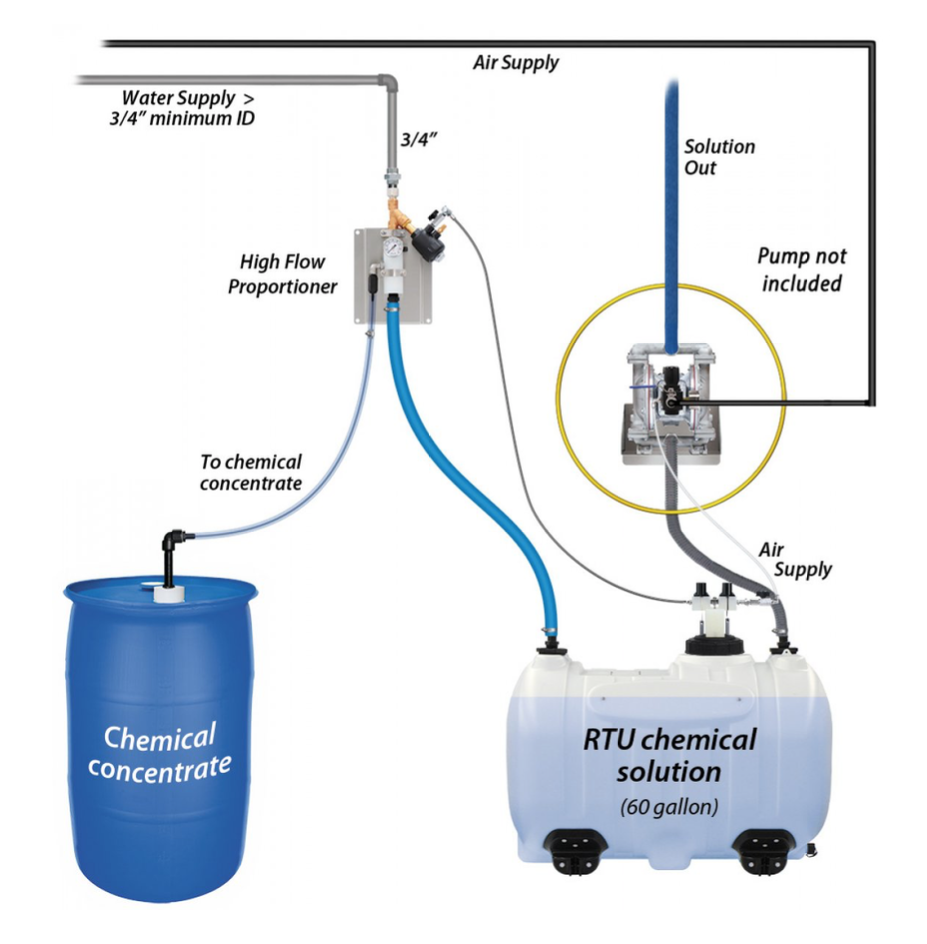

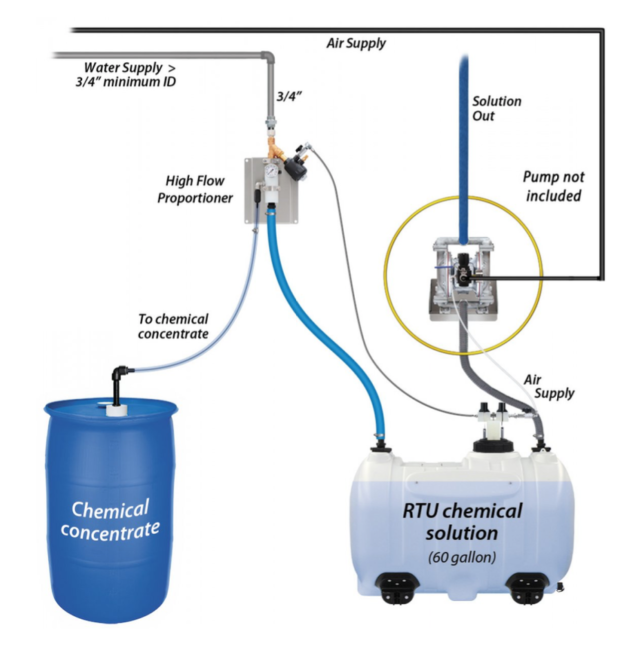

Proportioning & Foaming Systems

Our water driven chemical proportioning system will automatically refill a tank with ready-to-use chemical solution. When the solution in the tank drops below a pre-set level, the float valve triggers an air-activated solenoid to start the water flow. Using city water pressure, a venturi injection system draws and blends chemical concentrate into the water stream to create an accurately diluted solution. The system cycles continuously. Dual magnetic float valve design includes a primary valve to regulate normal operation and a secondary fail-safe valve to shut off the system if the primary float valve malfunctions.

Upon demand, an air driven pump system will transfer ready-to-use chemical solution to the foamer. The foamer creates foam by injecting compressed air into the solution to greatly increase volume and coverage ability. The foam is then projected through the discharge hose and nozzle on to any surface at distances up to 12 feet.

Proportioning & Foamer System

- Heavy-duty chemical tank with drain

- Magnetic float valves (primary and fail-safe) with polypropylene floats

- Air inlet ball valve

- Air-activated water solenoid

- Machined injector body

- Color-coded precision metering tips

- Polypropylene 1/2″ air-operated double diaphragm pump

- Compressed air ball valve & regulator/filter with gauge

- Chemical solution suction tube with strainer

- Discharge hose with MPT fitting

- Machined foamers

- Stainless steel inlet and discharge ball valves

- 50′ hoses, polypropylene foam wand & fan nozzle

- Stainless steel hose hangars

Sanitizing & Rinsing System

We can design combination systems for applying one chemical as foam, another chemical as a sanitizing spray and for rinsing. Using standard city water pressure, a venturi injection system draws and blends chemical concentrates into the water streams to create accurately diluted solutions using precision metering tips to control chemical usage. Compressed air is injected into the foaming solution which is then projected through the foam hose and fan nozzle. The sanitizer solution can be projected as a “flooding” spray for fast complete coverage. Finally, the system rinses at full pressure using stainless steel nozzles.

Features

- Designed for precision foam application, and to rinse and sanitize medium to large surfaces and objects

- Adjustable foam consistency (wet/dry)

- Stainless steel mounting bracket

- Stainless steel inlet and discharge ball valves

- Machined foamer and sanitizer bodies

- Color-coded precision metering tips to set dilution ratios

- Combo foam / sanitize hose, polypropylene foam wand and fan nozzle

- Rinse hose and stainless steel nozzle

Sanitizing Foggers

Foggers were typically used for sanitation in food and beverage facilities. Today, however, foggers and atomizers are now being used to easily apply disinfectants and sanitizers to hospitals, schools, hotels, airplanes, cruise ships, warehouses and public transit facilities.

Using compressed air, foggers atomize ready-to-use chemical disinfecting solutions and project the fog/mist particles into the air or onto exposed surfaces.

Foggers produce dry to wet fog, and come in range of models and sizes from small hand-held models to portable systems to permanent-mount, inline systems that can project particles up to 25 feet in 8 directions! Let our engineers help you design the optimal fogging system for your facility.

Self-Contained Portable Fogger Cart

Our Portable Fogger Cart is one of our most versatile models – perfect for schools, hospitals, doctor’s offices and hotels. Powered only by a standard 120V electrical connection, this portable, self-contained system comes complete with a quiet on-board compressor, fogger body, hose and thumb-gun on a stainless steel cart. With the thumb-gun, it allows you to deliver chemical fog precisely where you need it.

The system uses compressed air to draw pre-diluted chemical solution from a pail on the cart to the fogger body which atomizes the chemical and projects it as small to medium size “damp” particles at distances up to 15 feet. Fog (mist) fills the air and saturates exposed surfaces, including hard-to-reach areas. Just plug it in and go!

Features

- Stainless steel fogger body

- 120V air compressor

- 25′ twin-line air/chemical hose with activation ball valves

- 10 color-coded precision metering tips can refine the particle size by reducing chemical usage

- Stainless steel, 4 wheel cart assembly with hose rack

- Non-marking tires with stainless steel swivel casters

- Stainless steel metering tip holder

- Stainless steel construction ensures durability and years of outstanding performance

Portable 2-4 Way Fogger

The Portable 5 Gallon 2-4 Way Fogger is a chemical atomizer that uses compressed air and

venturi action to draw ready-to-use chemical solution from a 5 gallon pail on the cart through a

telescoping mast to the fogger body which atomizes the chemical and projects it as small to

medium size “damp” particles at distances up to 15 feet. Fog (mist) fills the air and saturates

exposed surfaces, including hard-to-reach areas.

Ball valves on two fogger bodies allow for conversion to 2-Way

fogging for narrow areas and the telescoping mast allows for

variable height adjustment up to 80 inches.

You can refine the particle size for your particular application

and manage chemical use by choosing different optional precise

metering tips.

Features

- (4) Four polypropylene fogger bodies mounted on adjustable mast

- (2) Two air ball valves to control air flow

- (2) Two 10′ chemical suction tubes and strainers

- (4) Four metering tip holders

- Stainless steel 2-wheel cart with non-marking tires

- Round stainless steel 5 gallon pail rack (square rack optional)

- Stainless steel, adjustable height fogger mast

Compact Hand-Held Fogger

The Compact Hand-Held Fogger is a chemical atomizer that uses compressed air and venturi

action to draw pre-diluted chemical solution from the attached bottle, atomize the chemical, and

project it as small to medium size “damp” particles at distances up to 15 feet.

It is easy to use! Just fill the bottle with your pre-mixed chemical/disinfectant, connect compressed

air, and press the thumb gun activator. Fog/mist will fill the air and saturate any exposed surfaces,

including hard-to-reach areas. You can refine the particle size and manage chemical use by

choosing the correct precise metering tip for your particular application.

Features

- Polypropylene fogger body attached to bottle top

- Lightweight wide-mouth, polyethylene quart bottle

- Thumb trigger gun with easy air hose connection

- 10 color-coded precision metering tips

- Metering tip holder

Pump Fed Foggers

Our Pump Fed Fogger is a chemical atomizer receives ready-to-use chemical from a central

chemical feed system and uses compressed air to atomize the solution and project it as small to

medium size “damp” particles up to 15 feet in 4 directions. Fog (mist) fills the air and saturates exposed surfaces, including hard-to-reach areas. It is also available as a 2 or 8 way fogger.

Air and chemical solution flow can be activated manually or activated in multiple zones throughout your facility using PLC controllers. A needle valve can refine the particle size for your particular application and

manage chemical use and a check valve prevents excessive dripping after shutdown.

Includes

- Machined polypropylene ceiling manifold

- Machined polypropylene fogger body

- Chemical needle valve

- Chemical check valve

Cleaning and effective disinfecting are critical elements to maintaining a healthy farm. It is not possible to completely sterilize every surface but it is important to do as much as possible to ensure that disease transmission is not likely to occur.

According to most veterinarians, the best practices for cleaning and disinfecting animal farms generally consists of the following six steps:

- Pre-clean – Pre-clean by removing excess organic material by scraping, shoveling, and sweeping. You can also pre-soak to soften dried waste and then pre-rinse. Soaking normally cuts down on the washing time.

- Clean – Do your main cleaning with an appropriately-sized pressure washing system and detergent. Hot and cold water can be used. Although it will speed up cleaning, hot water may cause steam and visibility problems in the winter. Pressure washers come in range of flow rates and pressure ratings so choose one that fits your operation and does not cause harm to the staff or facilities. Finally, choose a safe, effective cleaning solution to maximize your cleaning process. It will help break down and remove organics and grease better than plain water.

- Rinse – After washing, rinse all surfaces very well to remove loose waste, grease and detergent.

- Disinfect – Disinfection is the next critical step in the cleaning process to kill the bacteria. The Environmental Protection Agency (EPA) maintains an extensive list of approved disinfectants. Numerous industry and university sources can be utilized to help you choose the best one to fit your target pathogen. Most disinfectants are designed to be applied as foam. Foamers are especially effective with disinfectants since they increase the surface dwell time and assure complete coverage since they show exactly where the disinfectant has been applied.

- Final Rinse – A final rinse with the pressure washer is required to remove all of the disinfectant.

- Drying – Sufficient drying time is required to remove all moisture from the building and surfaces. Eliminating residual water can greatly decrease the survival rate of viruses and bacteria. If available, heaters can be used to evaporate as much water as possible before moving livestock back into the area. Although timing and space is often limited, it is recommended that the rooms be completely dried 2-3 times per year before moving the animals back to the rooms. This extra time will help dramatically reduce contamination.

We can work with your staff and custom-design a complete washing and water treatment system based on your needs.

For washing, rinsing and disinfection, we offer a range of pumping and pressure washing systems featuring manual, automated and Variable Frequency Drive controls. A Variable Frequency Drive (VFD) system is one of the most cost effective units to run and maintain and allows multiple users at the same time. Critical disinfection foaming and sanitizing systems can also be added to the washing/rinsing systems.

We also can help you treat the wash water so that it can be properly discharged. If the washing process produces a lot of solids, we have a range of solutions to first separate the solids from the wash water.

We provide the following equipment:

- Sanitizers and Foaming Systems

- Disinfection Fogging Systems

- VFD Controlled wash systems

- Electric Hot Water Pressure Washing Systems

- Cold Water Stationary Pressure Washing Systems

- Debris & solids baskets and screens

- Oil Water Separators

- Multi-media and polishing filtration

- Piping design assistance

- Tanks and control systems

If you are in the livestock industry and need a washing and water treatment solution, give us a call!

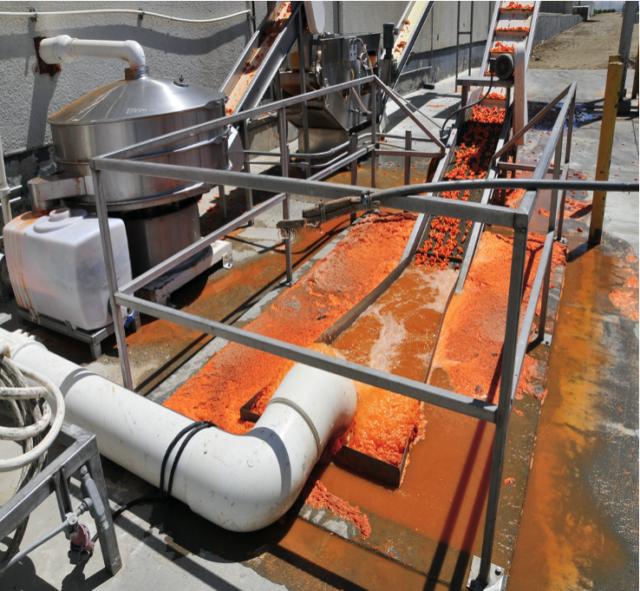

Food processing procedures are as varied as the food produced! The processing and packaging procedures for spaghetti sauce are a lot different from those of sausage, cheese and bread. And, each process produces their own unique waste streams.

That’s where we come in. We can work with your staff and custom-design a comprehensive washing and water treatment system based on your needs.

If you have to wash machinery, piping, conveyors, shelving or tanks, we can help you with pumping and heater packages featuring manual, automated and Variable Frequency Drive controls. A Variable Frequency Drive (VFD) system is one of the most cost effective units to run and maintain and allows multiple users at the same time. Different heating packages can be paired with the pumping and pressure washing systems so that you get the proper water temperature for your washing operation. Foaming, chemical injection and ozone disinfection systems can also be added to the washing systems, if required.

We can help you treat the wash water so that it can be properly discharged. If the washing process produces solids, we have a range of solutions to first separate the solids from the wastewater. After the solids are removed, we can process the water through our wastewater treatment systems.

We can help you treat the wash water so that it can be properly discharged. If the washing process produces solids, we have a range of solutions to first separate the solids from the wastewater. After the solids are removed, we can process the water through our wastewater treatment systems.

We provide the following equipment:

- VFD Controlled wash systems

- Hot and Cold Water pressure washers

- High efficiency heating systems

- Sanitizers and Foaming Systems

- Disinfection Fogging Systems

- Debris & solids baskets and screens

- Oil Water Separators

- Multi-media and carbon filtration

If you are in the food industry and need a washing and water treatment solution, give us a call now at 800-453-8639!

Our Polishing Pack Oil Absorbent Bags keeps your systems running cleaner and reduces environmental concerns by removing oil-related contaminants from water in sumps, recycling systems, and oil-water separators.

Benefits

- Excellent filtering capabilities

- Easy to handle and dispose of

- Cost efficient

- Custom shapes available to fit most separators

How do they work?

Water containing free oils enters the filter through the poly mesh cover. As the water flows around the multi-faceted oil-absorbing foam cells, the free oils are absorbed into the foam.

All water is repelled and continues to pass through the filter after the free oils are removed.

Typical Installation

Although they can be placed directly in the sump, the bags are typically installed with a flow dissipater plate in the clean water chamber of the oil water separator before the water is discharged to the sewer or surroundings.

They act as a polishing system by removing any floating oil sheens that may have passed through the separator. If the local sewer requirements are strict, the polishing system is highly recommended!

You can save money on your taxes when you purchase equipment by taking advantage of Section 179 of the IRS tax code. Section 179 allows business taxpayers to deduct the cost of certain property as an expense when the property is placed in service. It does not have to be depreciated out over several years. The Section 179 deduction applies to tangible personal property such as machinery and equipment purchased or leased for use in a trade or business, and if the taxpayer elects, qualified real property.

For tax years beginning after 2017, the TCJA increased the maximum Section 179 expense deduction from $500,000 to $1 million. The phase-out limit increased from $2 million to $2.5 million. These amounts are indexed for inflation for tax years beginning after 2018. For more information, see

https://www.irs.gov/newsroom/

Issue: An equipment rental company was expanding and they moved into a new facility

without a wash pad. There was plenty of indoor space but no outdoor space to put in a

new wash pad. The property owner did not want them to cut concrete or substantially

alter the property but our client still needed be able to wash their equipment onsite,

contain the water and discharge it properly to the sewer.

Solution: For a complete wash system, we recommended installing a SPT-10 Clarifier

Oil Water Separator System, an industrial-grade electric heated water pressure washer

with two portable hose reels, and a portable wash containment pad.

The portable wash pad allows them to wash as much as possible without any major

modifications to the property. They will also be able to move the entire system to a new

facility, if needed. The wash pad was equipped with pedestrian grating along both sides

so that the service personnel can work safely on a dry surface!

Above Ground Clarifier Oil Water Separator Flow Process

- The oil/water/sludge mixture enters the oil water separator

- The heavier sludge and particulates fall out of the fluid and are captured in the sludge hopper

- The oil and water mixture with lighter particulates travels up the inclined plates

- The inclined plates start to separate the mixture. Some oil rises to the top of the separator and the remainder of the particulates slide back down to the sludge hopper.

- The remaining oil and water mixture then moves through the coalescing media packs where the majority of the smaller oil particles attach to the media and combine together to form larger oil particles.

- These larger oil particles become so buoyant that they release from the media and travel to the top of the separator.

- As the oil volume in the separator reaches a certain level, the oil is drained to through piping to an oil storage tank.

- The clean water continues over the weir to the clean water chamber where it goes through a final polishing pack and out to the sewer.

WashBaySolutions.com offers a full line of oil and water separators that conform to the guidelines of API 421 for the removal of all free and dispersed non-emulsified oil and solids that settle from the waste stream. Get a Quote Today!

Oil Water Separator – Frequently Asked Questions

Please see a list of question and answers below related to our oil water separator products.

- How does the flow process work?

- How do you maintain an oil water separator?

- How does the oil separator remove the oil from water?

- What are the advantages to an oil water separator system?

- What is the difference between a clarifier oil water separator and an oil water separator?

- Why would you choose an above ground oil water separator vs. a below ground oil water separator?

- How to review and compare multiple oil water separators?

- What is the difference between Oil Interceptors vs. Oil Water Separators?