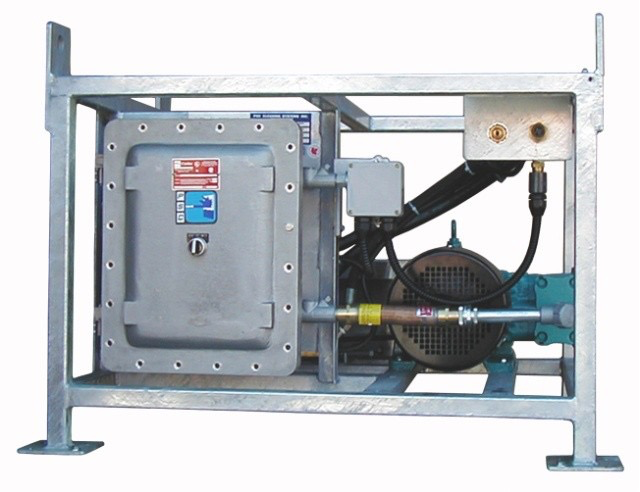

PSC Explosion-Proof high pressure washers are exceptionally well-engineered systems, CSA inspected and certified for use in Class 1, Division 1, Group C & D hazardous location environments. Depending on your application, they can built for onshore or offshore use. The offshore washers are equipped with stainless steel components to resist corrosion.

HOT WATER EXPLOSION-PROOF STANDARD SERIES FEATURES:

- General belt-driven, oil-bath plunger pump with pressure regulator (multi-gun capability) and powder coat painted pump cover with louvered end covers

- CSA approved / UL listed explosion-proof motor—1800 rpm, IP56 ingress protection, 1.15 service factor, class F insulation

- Non-direct immersion heat exchanger with #316 stainless steel heat exchange coil, Calrod elements with Incoloy sleeves, adjustable temperature controller and low water (heat exchanger fluid) level switchExplosion-Proof unit shown without accessories

- Fully automatic start / stop circuit with solid state time delay shutdown—controlled by trigger gun activation

- Steel cage construction with mounting feet and lifting eyes—powder coat painted

- Automatic high temperature shut down (thermo probe) for pump protection

- 50 ft. high pressure hose assembly complete with lance, trigger gun and chemical injection

- CSA approved / UL listed control box, heating elements, flexible coupling, conduit and seals

- CSA inspected and certified for use in Class 1, Division 1, Group C & D hazardous location environments

OFFSHORE SERIES FEATURES:

- Stainless steel pump cover with mesh/louvered end covers

- Steel cage construction with drip-proof pump base, mounting feet and lifting eyes—galvanized to ASTM123 and CSA G164-M1981 specifications

- Low inlet water pressure protection

COLD WATER EXPOSION PROOF STANDARD FEATURES:

- General belt-driven, oil-bath plunger pump with pressure regulator (multi-gun capability) and powder coat painted pulley guard

- CSA approved / UL listed explosion-proof motor—1800 rpm, IP56 ingress protection, 1.15 service factor, class F insulation

- Fully automatic start / stop circuit with solid state time delay shut down—controlled by trigger gun activation

- Steel cage construction with mounting feet and lifting eyes—powder coat painted

- Automatic high temperature shut down (thermo probe) for pump protection

- 50 ft. high pressure hose assembly complete with lance, trigger gun and chemical injection

- CSA approved / UL listed control box, heating elements, flexible coupling, conduit and seals

- CSA inspected and certified for use in Class 1, Division 1, Group C & D hazardous location environments

OFFSHORE SERIES ADDITIONAL FEATURES:

- Stainless steel pulley guard

- Steel cage construction with drip–proof pump base, mounting feet and lifting eyes—galvanized to ASTM123 and CSA G164–M1981 specifications

COMMON FACTORY ADDED OPTIONS:

- CAT plunger or piston pump

- SA nitrogen charged pulsation dampener

- SRA surge relief assembly (for flows of 6 gpm and greater)

- PG liquid-filled pressure gauge

- LWPP low inlet water pressure protection with reset

- ETM-EXA (D) integrated analog (digital) hour meter

- USC upstream (high pressure) chemical injection

- PCA-EX portability feature with phenolic casters and push/pull handle

- HRA 13 (16) high pressure hose reel assembly with 13 in. (16 in.) drum

- EGR-50 enclosed grounding reel with 50 ft. grounding wire and clamp