The SPT Series Integrated Sewer Pretreatment Systems have been specifically designed for treating wash water from commercial and industrial washing operations for acceptable discharge to a sanitary sewer. These heavy-duty stainless steel systems integrate an inclined plate clarifier with an oil water separator to remove heavy solids and floating oils.

The clarifier section will trap and remove coarse amounts of oil from the waste stream and remove as much Total Suspended Solids (TSS) as possible. The non-clogging plates allow for suspended solids to settle on the inclined plates and slide down to the sludge hopper, where they can easily be pumped out.

Our coalescing media will remove essentially all free and dispersed non-emulsified oils to an effluent concentration of less than 5 ppm. In a recent independent performance test, our customer fed 216,00 mg/l FOGs in and tested the effluent at a remarkable 4 mg/l/.

Review our SPT Clarifier Oil Water Separator Specifications Page

Review our SPT System 5 Stages OF Separation Flow Diagram

Features

- 304 Stainless Steel Construction

- Non-plugging Inclined plates to capture and contain settable solids

- Solids storage hopper

- Advanced European coalescing media designed to remove 99% of oil droplets

- Dual adjustable rotatable pipe skimmers

- On-board oil storage tank

- Removable vapor tight cover for access to chamber compartments

- Effluent compartment for pump out.

- Air or Electric Diaphragm Transfer Pump with Controller for automatic operation

- Low maintenance – no chemicals or filters to replace

SPT Specifications

| SPT-10 | SPT-20 | SPT-30 | SPT-50 | SPT-75 | SPT-100 | |

| Flow Rate | 1-10 GPM | 1-20 GPM | 1-30 GPM | 1-50 GPM | 1-75 GPM | 1-100 GPM |

| Tank Capacity | 300 Gal | 652 Gal | 645 Gal | 968 Gal | 1419 Gal | 1931 Gal |

| Sludge Volume | 27 Gal | 27 Gal | 45 Gal | 85 Gal | 85 Gal | 85 Gal |

| Product Tank | 40 Gal | 40 Gal | 40 Gal | 75 Gal | 75 Gal | 75 Gal |

| Approx. dimensions, FT | 3’W x 8’L x 5’H | 4’W x 8.5’L x 6’H | 4’W x 9’L x 6’H | 4’W x 9.75’L x 6’H | 4.5’W x 10’L x 7’H | 5.3’W x 10.5’L x 7.3’H |

| Construction | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

Optional Features

- pH control system

- Ozone system for odor control

- Polishing pack to remove trace oils

- Electric disk skimmers

- Automatic sludge dump systems

- Corrosion protection packages for high salt or corrosive applications

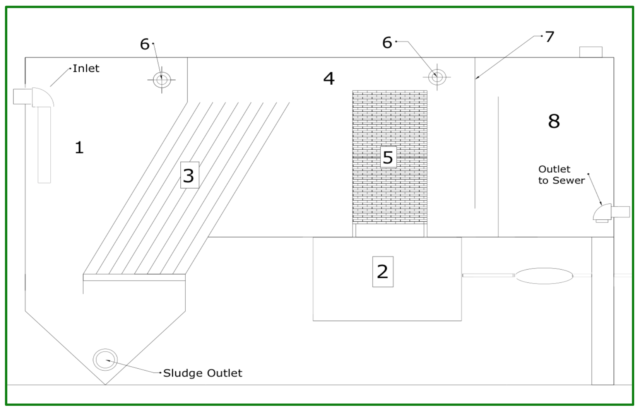

SPT- Systems Components

- Solids/Sand interceptor compartment – The water is pumped into the system through a non-clogging diffuser pipe to distribute the flow. The inlet interceptor chamber is designed to capture suspended solids, dissipate energy and begin separation.

- Pump and control – Water is pumped into the system via an air electric diaphragm pump with a pneumatic controller. Electric diaphragm pump and controllers are also available.

- Inclined Plates – Inclined plated above the sludge chamber catch suspended particles as the water stream moves into the separation chamber.

- Separation Chamber – After the water travels up the inclined plates, it flows into the stainless steel separation chamber containing the coalescing media.

- Coalescing Media Packs – Our high efficiency European coalescing media pack in the separation chamber further slows the water velocity so oil drops out of suspension and clings to the media. This advanced media will remove 99% of free oil droplets 20 microns or larger.

- Rotatable Oil Skimmers – Oil that has dropped out of suspension is then skimmed off the top of the separator and into a tank for easy removal.

- Baffles – An underflow weir will prevent re-suspension of solids while an oil retention weir will keep the oil in the separation compartment.

- Clean Water Chamber – The final stage is a clean water chamber where the clean water will flow out for reuse or to the drain.

Optional Equipment: Ozone generator to control odors: polishing pack to remove trace oils., and discharge pumps if needed.

Applications:

- Construction & Heavy Equipment Washing

- Mining Truck Washing

- Truck & Bus Washing

- Forklift Wash Facilities

- Oil & Gas Drilling Operations

- Locomotive Washing

- Marinas

These cost-effective systems will help satisfy local, state, and EPA environmental requirements as well as reduce water usage and operating costs. We offer a range of sizes and auxiliary wash equipment that can be engineered for your particular application.

Case Study: Sewer Pretreatment Systems

- Case Study of SPT Series system

to be processed before discharge to the sewer. [ read full study ]

This cost-effective system will help satisfy local, state, and EPA environmental requirements as well as reduce water usage and operating costs. We offer a range of sizes and auxiliary wash equipment that can be engineered for your particular application.

Frequently Asked Questions

- How does the flow process work?

- How do you maintain an oil water separator?

- How does the oil separator remove the oil from water?

- What are the advantages to an oil water separator system?

- What is the difference between a clarifier oil water separator and an oil water separator?

- Why would you choose an above ground oil water separator vs. a below ground oil water separator?