Our single wall or double wall below ground parallel, corrugated plate oil/water separators meet and exceed API 421 requirements, removing essentially 100% of dispersed non-emulsified oil droplets in the waste stream.

These separators are special purpose prefabricated parallel corrugated plate, cylindrical, gravity displacement oil water separators, containing an inlet compartment, sludge chamber, separation chamber, oil storage area and clean water compartment.

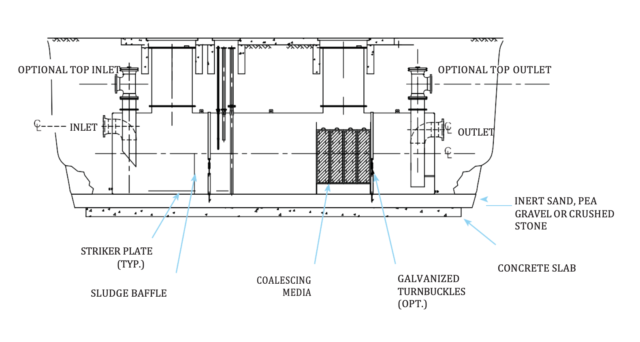

As shown below, the separation process if fairly simple. Wastewater flows into the inlet compartment. A baffle interrupts the flow and allows solids to drop out. Next the oil water moves into the separation chamber where our innovative media causes small oil droplets entrained in the water to coalesce into larger ones which then separate from the water and float to the surface. The clean water then travels into the clean water compartment through the outlet to the sewer.

Features

- Patented, revolutionary, non- plugging coalescing plates which remove free oil droplets as small as 20 microns

- Single wall or double wall construction with interstitial space for leak detection

- Rectangular access manhole with 3’ extension to service and maintain coalescing media

- Fittings for vent, oil pump out, sludge pump out, gauging and lifting lugs

- Exterior sandblasted and coated

- Will achieve discharge of 5 ppm or less in accordance with CEN EN 858-1

- Warranted for (5) years on material and workmanship and (30) years against external and internal corrosion

- Construction in accordance with UL58 and corrosion protection in accordance with UL1746

Options

- Internal coating for corrosion protection

- Grit chamber for high solids applications

- Hold down straps

- Leak and Level detection systems

Applications

- Parking Lots

- Re-fueling Facilities

- Marinas

- Military Installations

- Truck and Equipment Washes

How does it work?

Analysis

With these separators, we can provide analysis, which indicates that the separator will be provided with the required square feet of projected plate separation area to achieve the specified performance under laminar flow (i.e. Reynolds Number of less than 500) conditions. This service can include calculations signed by a registered professional engineer.

| Underground Oil Water Separator Specifications | |||

| Model # | Average Flow Rate (GPM) | Capacity (GALLONS) | Dimensions, D x L (FT) |

| WB-QB-342 | 35 | 350 | 3.5 x 6 |

| WB-QB-548 | 55 | 550 | 4 x 6 |

| WB-QB-1048 | 100 | 1000 | 4 x 10.75 |

| WB-QB-2064 | 200 | 2000 | 5.3 x 12 |

| WB-QB-3064 | 300 | 3000 | 5.3 x 18 |

| WB-QB-4064 | 400 | 4000 | 5.3 x 24 |

| Larger sizes available. | |||

Frequently Asked Questions

- How does the flow process work?

- How do you maintain an oil water separator?

- How does the oil separator remove the oil from water?

- What are the advantages to an oil water separator system?

- What is the difference between a clarifier oil water separator and an oil water separator?

- Why would you choose an above ground oil water separator vs. a below ground oil water separator?