We offer a complete line of high efficiency, stainless steel above ground oil water separators that will remove nearly all free and dispersed non-emulsified oil and settleable solids from the waste stream.

oil water separator design

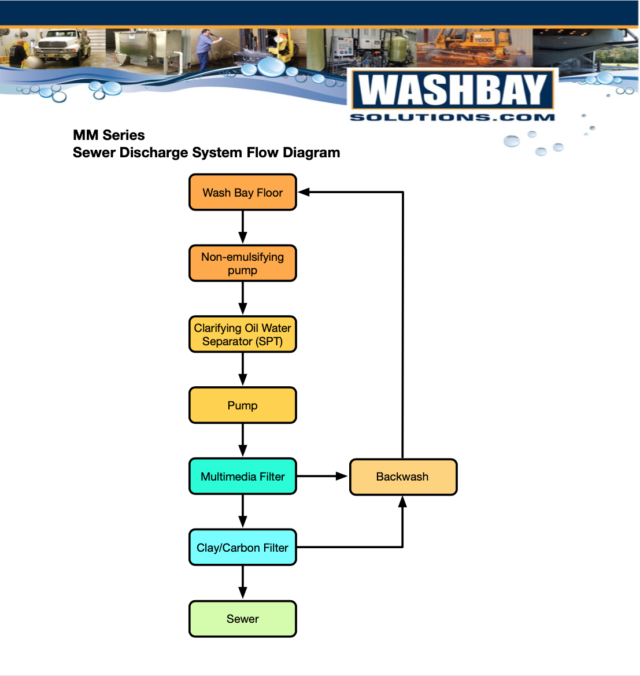

In some applications with extensive contamination, a simple oil water separator is simply not enough to treat the water prior to sewer discharge. Our heavy-duty MM-Series treatment systems treat wash water in multiple stages so it can be safely discharged to the sewer or, in many cases, the surroundings.

Stage 1 – Solids Settling

Almost all commercial washing operations produce some solids so the first stage of our filtration process is the solids handling system. We help you develop site-specific solutions to eliminate as many solids as possible before running the water through to the next stage of filtration. Solutions include custom-designed sumps, basins, trenches or screening systems.

Stage 2 – Oils & Solids Separation

After the coarse solids settling, the water is processed through either a multi-compartment stainless steel oil water separator or a stainless steel clarifier oil-water separator, which separates out smaller suspended solids, oil and water. In the first compartment of the clarifier oil water separator, free oils float to the surface. In the second section, the stainless steel clarifying plates remove coarse amounts of oil from the waste stream and remove as much Total Suspended Solids (TSS) as possible. The angles of the non-clogging plates are 55° which will allow any solids to slide down the plates into the solids hopper, where they can easily be pumped out. Finally, the coalescing media removes essentially 100% of all free and dispersed non-emulsified oils so the FOG effluent concentration can be as low as 5 ppm.

Stage 3 – Water Filtration & Polishing

After the clarifier oil-water separator, the water is pumped though a multi-media (sand, gravel, anthracite) filter and then safely discharged to the sewer or surroundings. Processed water passing through the system will be free of substantially all emulsified oils, waxes and other volatile organic compounds with only limited soaps and detergents remaining in the treated water. If needed, a blended activated carbon or a carbon/clay mixture tailored to a particular waste stream can be added as an optional polishing filter.

System Features

- Non-Ferrous Construction – Stainless Steel, PVC

- Fully-Automatic, pre-wired

- Clarifier Separator System

- Stainless Steel Clarifier Oil/Water Separator with 55° Hopper

- Advanced European coalescing media designed to remove oil droplets greater than 20 microns

- Electric or Air Diaphragm pump with controller

- Discharge Filtration System

- Automated Self-Cleaning Multi-Media and/or Clay/Carbon Fiberglass Filter Tank

- Heavy-duty, high efficiency Pump

- Sensors and interconnecting Schedule 80 plumbing

- NEMA-4X control panel

- PLC controller for automatic back wash operations

- All components mounted on heavy-duty stainless steel skid

Depending on the location, many options are available to maximize the efficiency of the wastewater treatment system including:

Optional Features

- Can be configured with existing equipment

- SCADA and remote monitoring UL/CSA Listing

- Transportable equipment rooms

- Rain Diverter Systems

- Chemical/Acid/Salinity Resistant Pumps & Components

- pH control system

TYPICAL MM-SERIES SYSTEM SPECIFICATIONS

|

MODEL |

MM-10/10 |

MM-35/20 |

MM-65/50 |

MM-100* |

|

DESIGN FLOW RATE, GPM |

1-10 |

1-25 |

10-55 |

30-100 |

|

COALESCING PLATE AREA, SF |

41 |

124 |

211 |

400 |

|

COALESCING MEDIA, CF |

4 |

8 |

24 |

48 |

|

CLARIFIER SEPARATOR SIZE, FT (WxLxH) |

3 x 7 x 5 |

3.5 x 8 x 6 |

4 x 10 x 6 |

5 x 11 x 7 |

|

NON-EMUSIFYING INFLUENT PUMP, GPM MAX |

20 |

50 |

75 |

125 |

|

MULTI-MEDIA, LBS |

300-500 |

500-1000 |

2500-2600 |

3700-4200 |

|

OPTIONAL POLISHING CLAY/CARBON, CF |

4-15 |

10-40 |

20-40 |

40 |

|

FILTER PUMP, HP |

1.5 |

2 |

3 |

5 |

|

DIRTY WATER STORAGE VOLUME, GAL |

500-750 |

500-1000 |

750-1000 |

1000-1500 |

|

CONTROL SYSTEM |

PLC, Automatic, Manual or Off |

|||

|

PUMP FRAME SIZE, FT (WxLxH) |

3 x 6 x 6.5 |

3 x 8 x 8 |

||

|

POWER REQUIREMENTS |

208 / 240 V 1 ph or 208 / 240 / 480 V 3 ph |

|||

* LARGER CAPACITY SYSTEMS (200-1500 GPM) ARE AVAILABLE

APPLICATIONS:

- Commercial Trucking

- Locomotive

- Mining

- Marine

- Forklift

- Oil and Gas Drilling

Problem: An engineer consulting with a railroad called with an application at a locomotive repair facility. Over time, lube oil and diesel fuel leaked from the locomotives into an inspection pit. Periodically, the oil along with sand and dirt collected in the pit was discharged into a retention pond. The oil was then skimmed from the surface of the pond and the water discharged to the sewer.

The roe skimmer wasn’t quite doing a good job so he asked us for suggestions on how to better treat the water before discharging to the sewer.

Solution: We recommended installing a SPT-20 Clarifier Oil Water Separator System with our standard air-driven pump and control system to treat the water. The clarifier section of the SPT-20 would remove all of the settleable solids while the coalescing media would remove all of the oil from the waste stream.

The SPT-20 did an excellent job of cleaning up the water during the week. The only issue reported was that their sump overflowed with water every weekend so their staff was met with too much water on the pad every Monday morning.

Our maintenance manager trouble-shot the entire system with their staff through Facetime, phone calls, and emails. A local electrician also tried to find the source of the problem since there were other issues at the facility. They tried multiple modifications but the problem persisted.

Finally, we engineered and assembled a hybrid control system just for their particular location and sent it out to them. The control system worked and the system is now fully operational and the client is very pleased.

Problem: A metals dealer and recycling company had a small wash outside area with a 900 gallon in-ground concrete sump adjacent to it. The sump captured both the wash water and storm water coming off the pad. Contaminants included compressor oil, motor oil, transmission fluid and gasoline.

The company called and asked us for suggestions on how to treat the water before discharging to the sewer. The nearest building to the sump was several hundred feet away and they had very limited area inside it to install an oil water separator.

Solution: This was a perfect application for our transportable equipment rooms. To treat the water, we installed an oil water separator with an electric diaphragm pump in a 20′ long container, our TER-20. Since the client was located in a northern climate, we added insulation and a heating system to the TER-20 to guard against freezing issues.

We placed the TER-20 on a pad adjacent to the in-ground sump and it took less than a day to hook up all of the electrical and plumbing lines to make the system operational.

Using the TER-20 saved the client building costs and provided additional storage space. It also allows them the flexibility to move the entire oil water separator system to a different facility when needed.

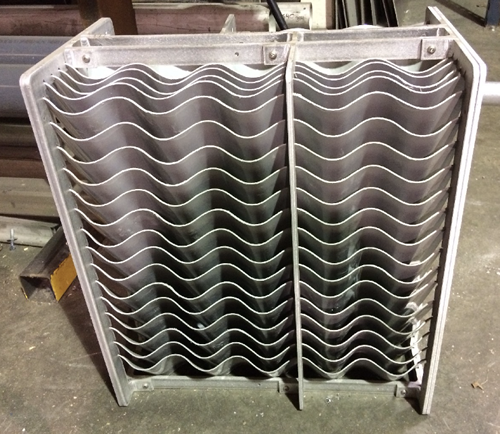

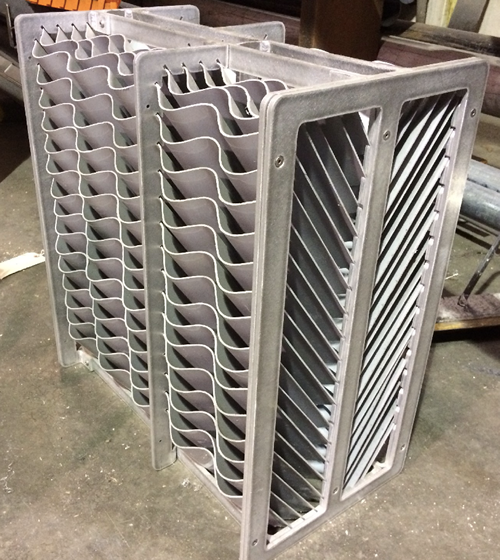

Oil Water Separator Media

In many washing applications, solids are a main component of the washing process. Heavy solids such as rocks and muck are often washed off and fall onto the wash pad where they can be easily removed. Other, finer settleable and suspended solids, however, often become entrained in the oily wash wastewater. Separating these settleable or suspended solids from the oily wash water is critical so that they do not clog the separator media and interfere with the oil water separation process.

To insure our oil water separators work well in a high solids environment without clogging, we have introduced a new coalescing media with a corrugated, cross-flow design.

This new media design is both unique and simple. As the water enters the separator, the flow is directed evenly across the surface of the media plates. The solids are captured and fall to the trough area of the corrugated plates below and the oils rise and stick to the trough area of the plates above. This design maintains laminar flow throughout the media so the oil and solids do not remix. Since the plates are smooth, the solids slide down the corrugated plates to the hopper area where they can be easily removed. Separated oil flows upwards along the plates to the top of the separator where it can be removed.

- Available in stainless steel, PVC, HPVC and polypropylene

- Plate spacing of ½”, ¾” or 1 ¼” depending on application

- Supplied in blocks for easy installation and removal

By coupling high efficiency separation with easy maintenance, this new media will ensure your oil water separator

operates at peak performance for years to come.

Give us a call at 800-453- 8639 for more information!

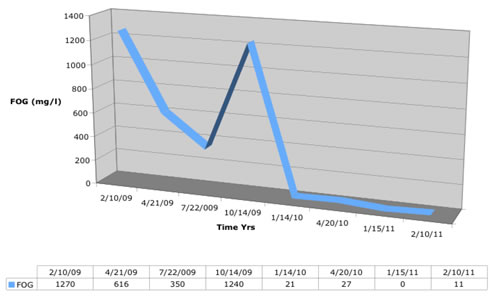

Issue: A major forklift manufacturer had an old oil water separator which had failed. The source of the water was a combination of coolants, wash waters, mop waters, as well as a pressure washer water. Over a four-quarter period, the company’s routine certified quarterly wastewater testing results showed fat, oils, and grease levels of 350 to 1270 mg/l discharging to the sewer, which was well in excess of the local limit of 100 mg/l.

Solution: The following year, the company purchased a Wash Bay Solutions SPT-10 to replace the existing separator. Over the next four quarters, the FOG in the wastewater averaged 14.75 mg/l. The actual test results were: 21, 27, 0, and 11mg/l.

Industrial Manufacturing Plant Fat and Grease (mg/I) vs. Time Oil Water Separator replaced with Wash Bay Solutions SPT System

Due to the unique design of the SPT unit, it has more opportunity to separate oil and grease than the typical oil water separator. While the SPT is not designed to break an emulsion, due it’s multiple compartments, it can trap and hold back some emulsions. Since it introduction, the SPT has been shipped to many different countries throughout the world. Additionally, many Fortune 500 companies have standardized the unit in their facilities, plants, and processes.

[box type=”alert”]SOLD – NO LONGER AVAILABLE

PLEASE CALL 800.453.8639 FOR ADDITIONAL DETAILS ON OUR PRODUCTS[/box]

RE-FURBISHED EQUIPMENT – For Sale or Lease

SPT-50 Clarifier Oil Water Separator System – The SPT-50 was designed for use in heavy industrial washing operations as a pre-treatment system to remove free oils, grease and high TSS from the waste stream. It is a two-part system designed to be simple to operate but very effective in its ability to remove oil and solids from the waste stream. The first clarifier section will trap and remove coarse amounts of oil from the waste stream and remove as much Total Suspended Solids (TSS) as possible. The plates will also capture larger bubbles of oil and liberate them from the waste stream before they get to the secondary oil water separator section. In that section, coalescing media will remove essentially all free and dispersed non-emulsified oils to an effluent concentration of less than 5 ppm. The entire system can be easily cleaned and maintained.

Standard Features:

- 1-50 GPM Capacity

- Stainless Steel Construction

- Advanced coalescing media designed to remove oil droplets greater than 20 microns

- Projected plate inclined plates to direct the flow to the surface

- Sludge hopper to capture and contain settleable solids.

- Adjustable rotatable pipe oil skimmers

- Air diaphragm transfer pump and pneumatic level sensor

- Internal oil storage tank

- Utilities Required: Air 30 CFM @ 40 psi

- Approximate dimensions: 9’ 8” L x 4’ 10” W x 5’ 10” H

Extra Features Available:

- pH Control System

- Dual stainless steel floating skimmers

- 3-way skimmer selector valve and piping manifold

- Control panel, 4 float switches and wiring harness

- Automated 2 and 3-way valve systems

- Ozone System to Control Odors, 120V

At Wash Bay Solutions, our emphasis is on quality. These systems are exceptionally well-engineered and designed for heavy-duty commercial and industrial operations. Simple to operate and maintain, they will run for years in the harshest environments.

This equipment has been re-furbished following less than a year’s use at an industrial washing facility. It is priced to sell or available for lease. Call us at 800-453-8639 for pricing information.

Problem: A gold mine in central Mexico was modifying their vehicle maintenance facility and adding a wash bay for their heavy mining trucks and vehicles covered with solids, dirt, oil, and grease. The mining company contacted an engineering firm in Arizona who then contacted us for our wash bay expertise.

Solution: We worked with the engineering firm to help design the wash bay with the proper pad layout to accommodate the enormous vehicles, substantial wash water volumes and large amounts of solids. We also had to account for rainwater volumes since their wash bay was uncovered.

Our SPT-50 Clarifier Oil Water Separator System was a perfect fit since it was designed for treating wash water from industrial washing operations with large solids concentrations. It includes a stainless steel clarifier oil water separator that has both a clarifier section, which will remove all settable solids and an oil water separator section, which will remove all non-emulsified oil from the waste stream.

During construction of the wash pad and installation of the SPT-50, we continued to work with the engineering company so insure all tasks were completed properly. We provided all manuals and documentation in both Spanish and English so that as little information as possible was lost in translation. The client has reported that the SPT-50 has been working very well since installation.

Oil and water separator systems and water reclaim systems are generally used in commercial settings to remove oil and solids from wastewater effluents. Electrical substations, chemical plants, and oil refineries utilize this technology every day. There are two main types of systems, sewer pre-treat systems and closed-loop systems. Sewer pre-treat systems will treat and clean the water so that it can be discharged into the local sewer system. A closed loop system will treat the water so that it can be reused onsite.

In an oil water separator, the corrugated plates intercept oil droplets as the wastewater travels through the separator. New droplets coalesce (combine) with retained droplets, and the droplets become larger. Enlarged droplets are released from the water and rise to the surface where they are decanted into a storage tank, and then properly disposed of with any local or government waste management facility.

Washbay Solutions offers a complete line of the best oil water separators and water reclaim systems on the market today. Whether above or belowground, a closed-loop or sewer pre-treat system, Washbay Solutions has the right system to fit the needs of your company.

A case study was conducted of our sewer pre-treat system at one of our customers located in one of the strictest sewer authorities in North Carolina. After assisting our customer with obtaining a permit, we also helped save them thousands of dollars on a water meter required by the permit. Our client was very pleased with the system, and we returned quarterly to assist with and coordinate water analyses required by their permit. As the water analyses results kept proving our system was cleaning the water remarkably well, the permit requirements kept decreasing which saved our client thousands of dollars in analyses costs.

Another case study was conducted of our closed-loop system at a trucking company. Since they were located outside of the local sewer limits, they needed to be able to clean and recycle their own wastewater. In May of 2007, we assisted the trucking company with the installation of a closed-loop water reclaim and separation system that is used on a daily basis today. We still provide quarterly inspections to ensure the closed loop system is working as designed.

Whether your company is looking for a closed-loop or a pre-sewer treatment system, Washbay Solutions can help design the system that is right for you.

Headquarters

WashBay Solutions International