Problem: A facilities manager with a national maintenance company called looking for a corporate solution for their wash pads. They were expanding into several new markets and wanted to standardize their washing and water treatment systems.

Complications included the fact that most of their vehicles are sweeper trucks which generate a lot of solids. A typical wash yields 1/3 yard of solids. With each facility washing 10+ units per day, the amount of solids generated per month was substantial. Also, each facility has a slightly different layout. The good news was that most of them were connected to the municipal sewer.

Solution: Since their solids handling issues needed to be addressed in addition to their washing and water treatment issues, we offered our engineering services to help them design a custom solution that they could standardize as much as possible for their wash bays and solids settling basins.

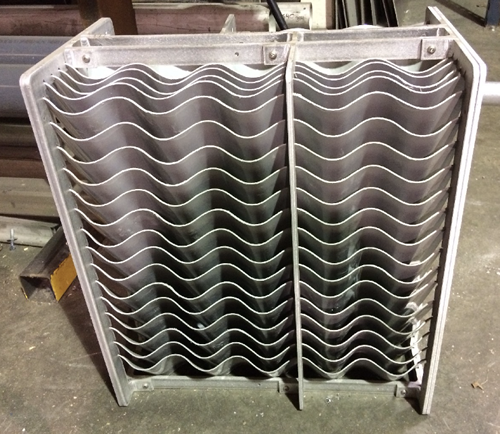

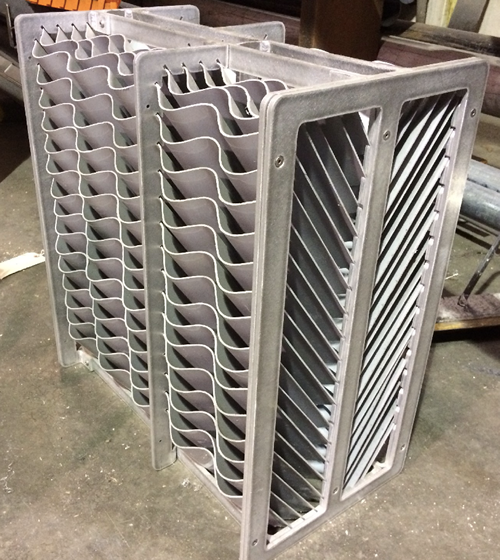

Once we completed the design, we recommended a number of washing and treatment options based on their desired washing processes. Due to the fact that they had a variety of vehicles and equipment, they decided on both a demucking system and pressure washing system for washing. The demucking system was paired with a partial water reclaim system to recycle the water multiple times before the water was sent through our SPT-20 Clarifier Oil Water Separator System to process it for acceptable discharge to the sewer.

Finally, all of the equipment was installed in a TER-20 Transportable Equipment Room. This will save installation costs as well as allow the customer to move the equipment to a different location in the future. It also saves space inside of the customer’s building for other critical activities.