We can help you design multi-function systems consisting of proportioning, sanitizing, foaming and/or rinsing systems.

Proportioning & Foaming Systems

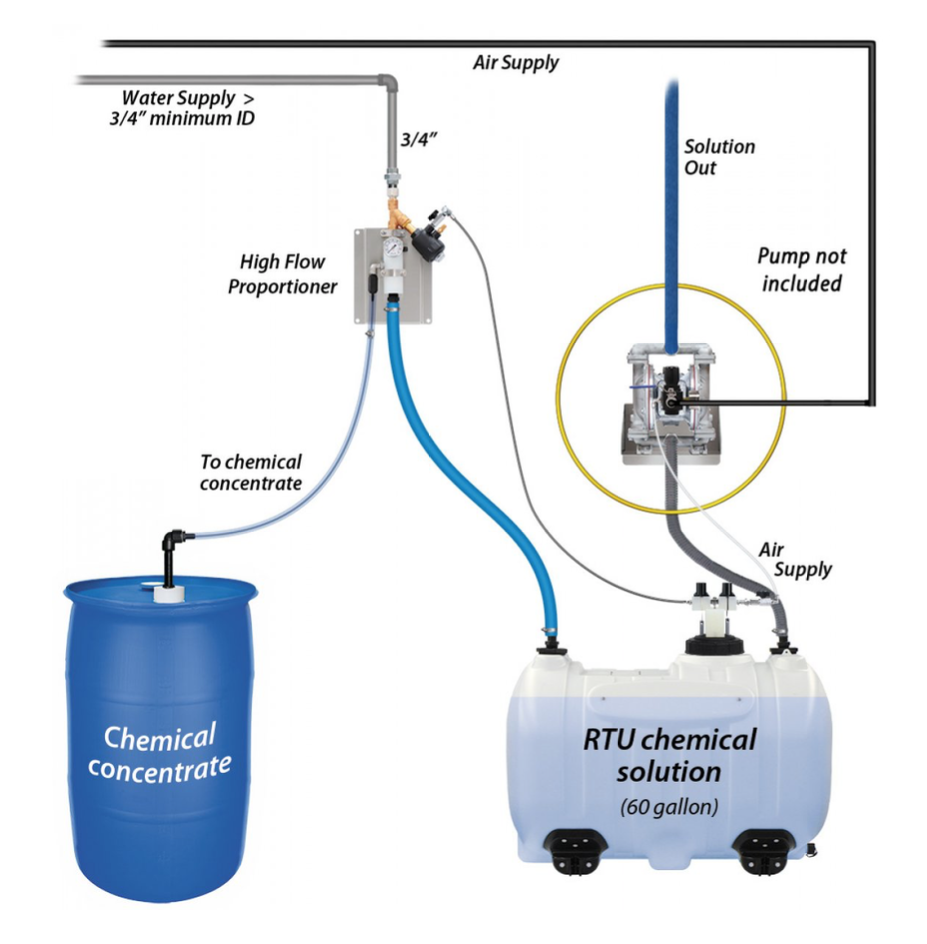

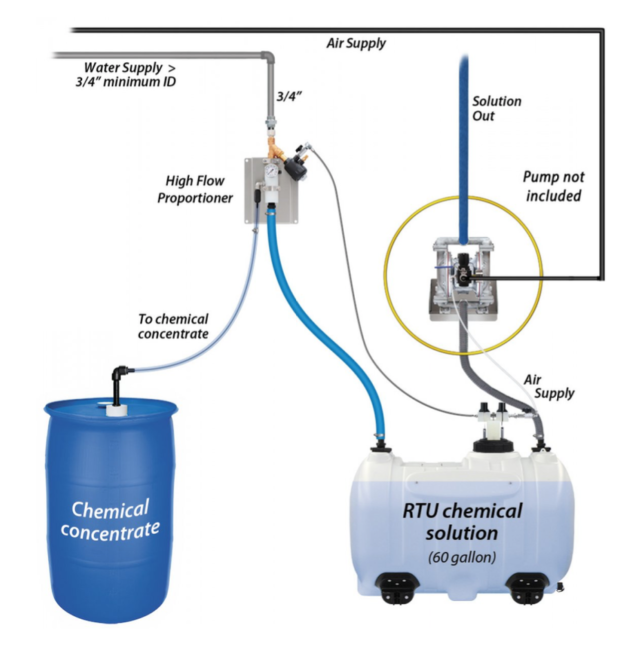

Our water driven chemical proportioning system will automatically refill a tank with ready-to-use chemical solution. When the solution in the tank drops below a pre-set level, the float valve triggers an air-activated solenoid to start the water flow. Using city water pressure, a venturi injection system draws and blends chemical concentrate into the water stream to create an accurately diluted solution. The system cycles continuously. Dual magnetic float valve design includes a primary valve to regulate normal operation and a secondary fail-safe valve to shut off the system if the primary float valve malfunctions.

Upon demand, an air driven pump system will transfer ready-to-use chemical solution to the foamer. The foamer creates foam by injecting compressed air into the solution to greatly increase volume and coverage ability. The foam is then projected through the discharge hose and nozzle on to any surface at distances up to 12 feet.

Proportioning & Foamer System

- Heavy-duty chemical tank with drain

- Magnetic float valves (primary and fail-safe) with polypropylene floats

- Air inlet ball valve

- Air-activated water solenoid

- Machined injector body

- Color-coded precision metering tips

- Polypropylene 1/2″ air-operated double diaphragm pump

- Compressed air ball valve & regulator/filter with gauge

- Chemical solution suction tube with strainer

- Discharge hose with MPT fitting

- Machined foamers

- Stainless steel inlet and discharge ball valves

- 50′ hoses, polypropylene foam wand & fan nozzle

- Stainless steel hose hangars

Sanitizing & Rinsing System

We can design combination systems for applying one chemical as foam, another chemical as a sanitizing spray and for rinsing. Using standard city water pressure, a venturi injection system draws and blends chemical concentrates into the water streams to create accurately diluted solutions using precision metering tips to control chemical usage. Compressed air is injected into the foaming solution which is then projected through the foam hose and fan nozzle. The sanitizer solution can be projected as a “flooding” spray for fast complete coverage. Finally, the system rinses at full pressure using stainless steel nozzles.

Features

- Designed for precision foam application, and to rinse and sanitize medium to large surfaces and objects

- Adjustable foam consistency (wet/dry)

- Stainless steel mounting bracket

- Stainless steel inlet and discharge ball valves

- Machined foamer and sanitizer bodies

- Color-coded precision metering tips to set dilution ratios

- Combo foam / sanitize hose, polypropylene foam wand and fan nozzle

- Rinse hose and stainless steel nozzle